About Us

Milltrust International Group is co-headquartered in the asset management hubs of London and Singapore, with a local presence, affiliates, and strategic partnerships spanning across the globe.

Asset Management

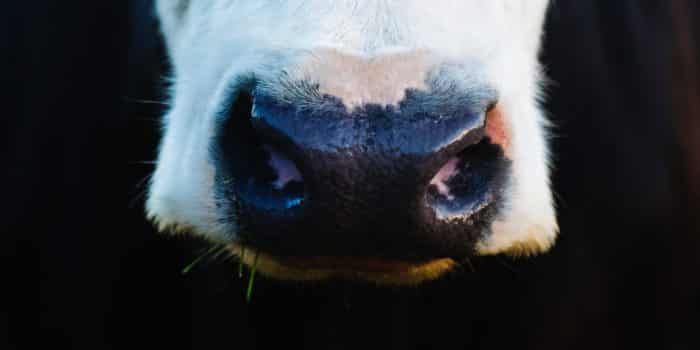

Milltrust delivers sustainable investment solutions in public and private markets, focusing on ‘One Health’ and addressing emerging economies, food demand, technology, and climate change, aligning wealth with sustainable prosperity.

Wealth Management

East West Private Wealth stands as a premier global Multi-Family office, offering unparalleled, tailored wealth management services and sustainable, eco-conscious investment solutions, crafting legacies across the globe with transparency, flexibility, and integrity.

News

All the latest news, articles, commentaries, press releases, and media coverage of Milltrust International Group and its affiliates.

Contact Us

Milltrust International Group is co-headquartered in the asset management hubs of London and Singapore, with regional presence and strategic partnerships around the world.