At Milltrust, we understand that the future of food production is of paramount importance as the world population continues to grow, and the pressure to produce food in a sustainable manner increases. The reduction of dependence on traditional farming methods is crucial to meet the demands of the future. One of the many answers, with its cost-effective and sustainable approach, may be precision fermentation.

Precision fermentation saw a meteoric rise in 2022, propelled by the surging demand for sustainable and alternative food production methods. In particular, the dairy industry embraced precision fermentation technology with open arms, driven by the need to address their own greenhouse gas emissions after years of the spotlight solely being on the meat industry. Investment in alternative dairy, specifically fermented protein and not plant-based, has seen a significant increase in recent years. In 2015, 2016, and 2017, funding for this area was under $25 million each year. By 2021, funding had reached an all-time high of $1.7 billion [Pitchbook FoodTech report 2021]. The most significant transactions were two late-stage rounds, each totalling $350 million, for Nature’s FYND and Perfect Day. The numbers are impressive; the Global Precision Fermentation Market size is expected to reach $11.8 billion by 2028, rising at a market growth of 41.5% CAGR during the forecast period. [Share & Industry Trends Analysis Report By Microbe 2022]

Across the alternative protein industry, precision fermentation is growing the quickest, representing 1.5 tonnes of new capacity every year or 4,000 tonnes per day [Pitchbook AgTech report 2022]. From China to India to the Middle East, precision fermentation start-ups are proliferating globally, indicating the growing prevalence and investment in this technology across various regions and industries.

Fermentation has been used in food production for hundreds of years; for example, beer, wine, yogurt, bread, cheese, pickles, sauerkraut, kimchi, soy sauce, miso, and many more. The three main types of fermentation — biomass, precision, and gas — each have their own unique advantages when it comes to producing alternative proteins. Biomass fermentation is the most common type of fermentation, and it involves the use of microorganisms to convert organic matter into a variety of products. Gas fermentation is the second type of fermentation, and it involves the use of microorganisms to convert gases, such as carbon dioxide, into valuable alternative proteins. Precision fermentation, heterologous production, is a targeted approach that genetically modifies microorganisms to create specific alternative proteins, such as enzymes, antibiotics (penicillin has been created this way for decades), and now food. It aims to produce high-quality alternative proteins, similar to traditional food sources, at a lower cost, and with minimal environmental impact.

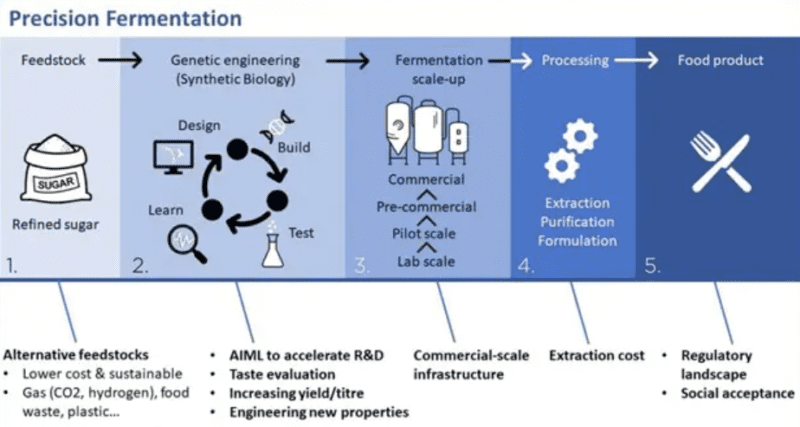

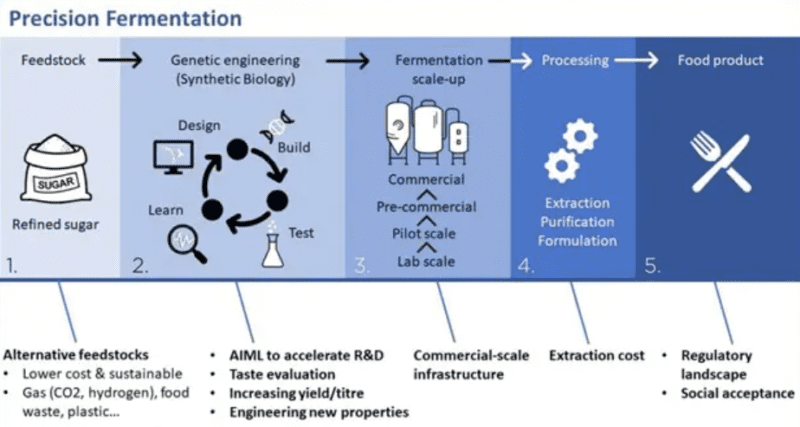

Precision fermentation involves using microbes as cell factories to produce specific ingredients by manipulating their DNA through strain engineering. This allows for the directed production of a desired molecule or compound, such as a protein, by altering the host organism’s genetic instructions. Initially, the microflora and genetic blueprint responsible for producing the targeted substance are obtained. These are then incorporated into a fermentation vessel containing water, essential nutrients, and a carbohydrate substrate. These tanks are frequently of substantial size, akin to industrial structures. The microorganisms metabolize the sugars, forming the desired product, which is subsequently purified and dried into a powdered form. This powder, by no means the finished product, can be incorporated as an ingredient in other products, such as plant-based protein or cultivated meat. Many companies are already benefitting from precision fermentation; for example, Every (egg proteins), Geltor (collagen and gelatin), Mycotechnology (meat and dairy), and Perfect Day (milk protein).

Precision Fermentation Process; Source: The Commonwealth Scientific and Industrial Research Organization (CSIRO)

In traditional farming, the animals are the bioreactors. Animals eat basic food grains and then convert them into nutrients. However, you have a limited control over the production process, unpredictable results, risk of pathogenic transmission and animal-borne pathogens, and a much higher environmental impact. Precision fermentation will never fully replace traditional methods and nor should it, however it does help solve these issues, it uses 99% less water, 97% less greenhouse gases, and up to 60% less energy use than the exact same process through animals [Perfect Day, Inc.].

Optimizing the type and cost of the substrate used to feed the microbes is crucial for achieving economic viability and sustainability in fermentation processes, as it is one of the major expenses for most companies in the industry. Currently, sugars are the predominant substrate employed within the fermentation industry. As the field progresses, an increasing number of companies are likely to adopt methanol as a substrate. The utilization of methanol as a raw material is sustainable (not always, but it can be produced in an environmentally friendly manner) and has advantages over gaseous fermentation, such as its liquid form, which makes it more amenable to fermentation.

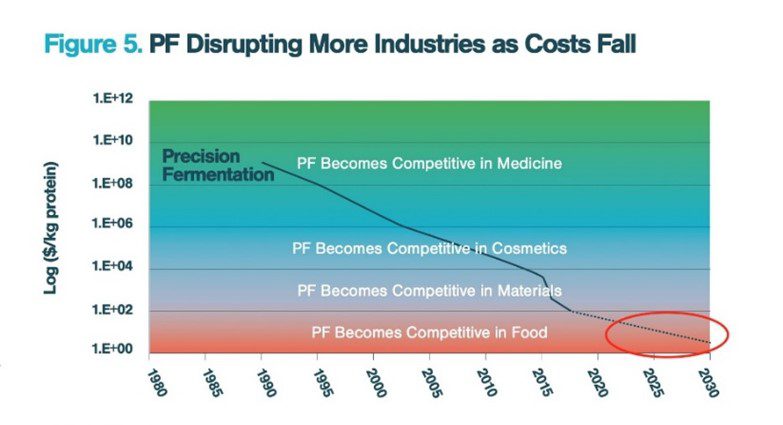

Scaling up precision fermentation technology currently poses three main challenges: achieving a cost-competitive price for sustainable protein compared to traditional sources, supply of the bioreactors themselves (currently only large multinationals such as DuPont and Cargill supply them), and regulatory hurdles.

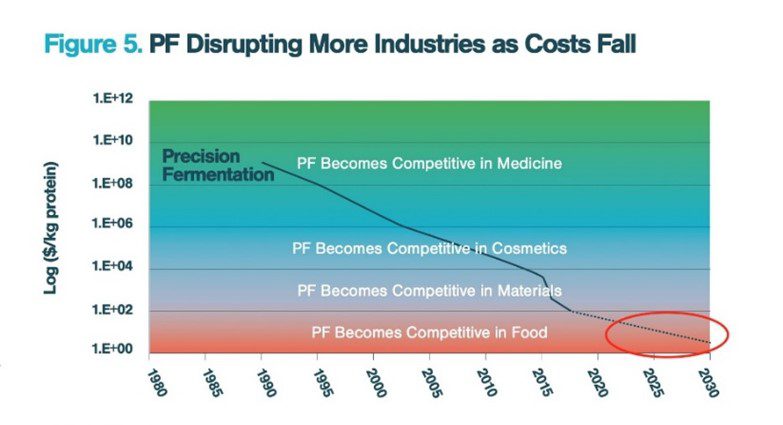

Scaling up process; Source: RethinkX

Liberation Labs is a company that addresses the issues related to scaling up precision fermentation; their 600 and 4,000 M3 facilities are purpose built for precision fermentation, driving reduced cost, increased yield, and process efficiency for novel food manufacturing. The company recently closed a $20m seed funding round, led by Agronomics and Siddha Capital, to continue their efforts in this area.

To conclude, precision fermentation is a technology that has the potential to revolutionize the way we produce food. Its ability to produce high-quality ingredients that are identical to traditional food sources, at a fraction of the cost, and with a reduced environmental impact makes it an attractive option for food manufacturers.

Recognizing this, Milltrust has partnered with Earth First Food Ventures to launch the Smart Protein Fund. This fund aims to provide the necessary financial resources to companies in the precision fermentation space, allowing them to expand their operations and bring their products to market. By providing access to capital, the Smart Protein Fund is playing a vital role in driving the growth and development of the precision fermentation industry and alternative protein industry as a whole.